This sponsored article is brought to you by NYU Tandon School of Engineering.

In a significant advancement for the field of drug delivery, researchers have developed a new technique that addresses a persistent challenge: scalable manufacturing of nanoparticles and microparticles. This innovation, led by

Nathalie M. Pinkerton, Assistant Professor of Chemical and Biomolecular Engineering at the NYU Tandon School of Engineering, promises to bridge the gap between lab-scale drug delivery research and large-scale pharmaceutical manufacturing.

The breakthrough, known as Sequential NanoPrecipitation (SNaP), builds on existing nano-precipitation techniques to offer improved control and scalability, essential factors in ensuring that drug delivery technologies reach patients efficiently and effectively. This technique enables scientists to

manufacture drug-carrying particles that maintain their structural and chemical integrity from lab settings to mass production—an essential step toward bringing novel therapies to market.

Using 3D Printing to Overcome a Challenge in Drug Delivery

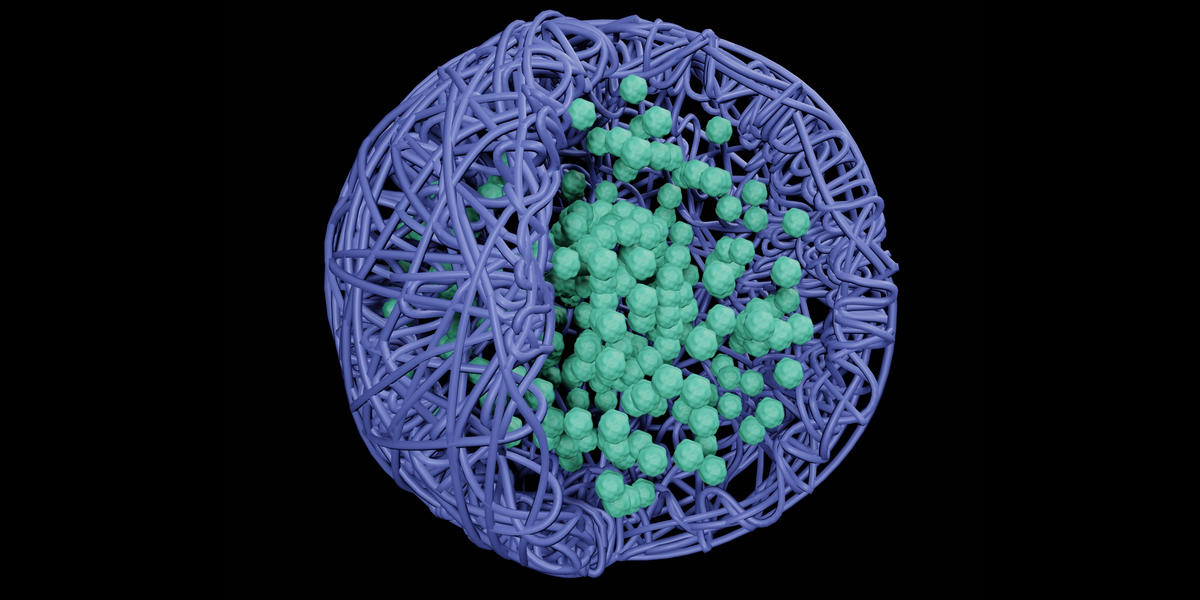

Nanoparticles and microparticles hold tremendous promise for targeted drug delivery, allowing precise transport of medicines directly to disease sites while minimizing side effects. However, producing these particles consistently at scale has been a major barrier in translating promising research into viable treatments. As Pinkerton explains, “One of the biggest barriers to translating many of these precise medicines is the manufacturing. With SNaP, we’re addressing that challenge head-on.”

Pinkerton is an Assistant Professor of Chemical and Biomolecular Engineering at NYU Tandon.NYU Tandon School of Engineering

Pinkerton is an Assistant Professor of Chemical and Biomolecular Engineering at NYU Tandon.NYU Tandon School of Engineering

Traditional methods like Flash Nano-Precipitation (FNP) have been successful in creating some types of nanoparticles, but they often struggle to produce larger particles, which are essential for certain delivery routes such as inhalable delivery. FNP creates polymeric core–shell nanoparticles (NPs) between 50 to 400 nanometers in size. The process involves mixing drug molecules and block-copolymers (special molecules that help form the particles) in a solvent, which is then rapidly blended with water using special mixers. These mixers create tiny, controlled environments where the particles can form quickly and evenly.

Despite its success, FNP has some limitations: it can’t create stable particles larger than 400 nm, the maximum drug content is about 70 percent, the output is low, and it can only work with very hydrophobic (water-repelling) molecules. These issues arise because the particle core formation and particle stabilization happen simultaneously in FNP. The new SNaP process overcomes these limitations by separating the core formation and stabilization steps.

In the SNaP process, there are two mixing steps. First, the core components are mixed with water to start forming the particle core. Then, a stabilizing agent is added to stop the core growth and stabilize the particles. This second step must happen quickly, less than a few milliseconds after the first step, to control the particle size and prevent aggregation. Current SNaP setups connect two specialized mixers in series, controlling the delay time between steps. However, these setups face challenges, including high costs and difficulties in achieving short delay times needed for small particle formation.

A new approach using 3D printing has solved many of these challenges. Advances in 3D printing technology now allow the creation of precise, narrow channels needed for these mixers. The new design eliminates the need for external tubing between steps, allowing for shorter delay times and preventing leaks. The innovative stacked mixer design combines two mixers into a single setup, making the process more efficient and user-friendly.

“One of the biggest barriers to translating many of these precise medicines is the manufacturing. With SNaP, we’re addressing that challenge head-on.”

—Nathalie M. Pinkerton, NYU Tandon

Using this new SNaP mixer design, researchers have successfully created a wide range of nanoparticles and microparticles loaded with rubrene (a fluorescent dye) and cinnarizine (a weakly hydrophobic drug used to treat nausea and vomiting). This is the first time small nanoparticles under 200 nm and microparticles have been made using SNaP. The new setup also demonstrated the critical importance of the delay time between the two mixing steps in particle size control. This control over the delay time enables researchers to access a larger range of particle sizes. Additionally, the successful encapsulation of both hydrophobic and weakly hydrophobic drugs in nanoparticles and microparticles with SNaP was achieved for the first time by Pinkerton’s team.

Democratizing Access to Cutting-Edge Techniques

The SNaP process is not only innovative but also offers a unique practicality that democratizes access to this technology. “We share the design of our mixers, and we demonstrate that they can be manufactured using 3D printing,” Pinkerton says. “This approach allows academic labs and even small-scale industry players to experiment with these techniques without investing in costly equipment.”

A stacked mixer schematic, with an input stage for syringe connections (top), which connects immediately to the first mixing stage (middle). The first mixing stage is interchangeable, with either a 2-inlet or a 4-inlet mixer option depending on the desired particle size regime (dotted antisolvent streams only present in the 4-inlet mixer). This stage also contains pass-through for streams used in the second mixing step. All the streams mix in the second mixing stage (bottom) and exit the device.

A stacked mixer schematic, with an input stage for syringe connections (top), which connects immediately to the first mixing stage (middle). The first mixing stage is interchangeable, with either a 2-inlet or a 4-inlet mixer option depending on the desired particle size regime (dotted antisolvent streams only present in the 4-inlet mixer). This stage also contains pass-through for streams used in the second mixing step. All the streams mix in the second mixing stage (bottom) and exit the device.

The accessibility of SNaP technology could accelerate advances across the drug delivery field, empowering more researchers and companies to utilize nanoparticles and microparticles in developing new therapies.

The SNaP project exemplifies a successful cross-disciplinary effort. Pinkerton highlighted the team’s diversity, which included experts in mechanical and process engineering as well as chemical engineering. “It was truly an interdisciplinary project,” she noted, pointing out that contributions from all team members—from undergraduate students to postdoctoral researchers—were instrumental in bringing the technology to life.

Beyond this breakthrough, Pinkerton envisions SNaP as part of her broader mission to develop universal drug delivery systems, which could ultimately transform healthcare by allowing for versatile, scalable, and customizable drug delivery solutions.

From Industry to Academia: A Passion for Innovation

Before arriving at NYU Tandon, Pinkerton spent three years in Pfizer’s Oncology Research Unit, where she developed novel nano-medicines for the treatment of solid tumors. The experience, she says, was invaluable. “Working in industry gives you a real-world perspective on what is feasible,” she points out. “The goal is to conduct translational research, meaning that it ‘translates’ from the lab bench to the patient’s bedside.”

Pinkerton — who earned a B.S. in Chemical Engineering from the Massachusetts Institute of Technology (2008) and a doctoral degree in Chemical and Biological Engineering from Princeton University — was attracted to NYU Tandon, in part, because of the opportunity to collaborate with researchers across the NYU ecosystem, with whom she hopes to develop new nanomaterials that can be used for controlled drug delivery and other bio-applications.

She also came to academia because of a love of teaching. At Pfizer, she realized her desire to mentor students and pursue innovative, interdisciplinary research. “The students here want to be engineers; they want to make a change in the world,” she reflected.

Her team at the Pinkerton Research Group focuses on developing responsive soft materials for bio-applications ranging from controlled drug delivery, to vaccines to medical imaging. Taking an interdisciplinary approach, they use tools from chemical and materials engineering, nanotechnology, chemistry and biology to create soft materials via scalable synthetic processes. They focus on understanding how process parameters control the final material properties, and in turn, how the material behaves in biological systems — the ultimate goal being a universal drug delivery platform that improves health outcomes across diseases and disorders.

Her SNaP technology represents a promising new direction in the quest to scale drug delivery solutions effectively. By controlling assembly processes with millisecond precision, this method opens the door to creating increasingly complex particle architectures, providing a scalable approach for future medical advances.

For the field of drug delivery, the future is bright as SNaP paves the way toward an era of more accessible, adaptable, and scalable solutions.